Designing for durable concrete presents a special challenge for specifiers. Concrete is usually specified based on a particular physical property such as compressive strength, but there is no single test to evaluate ‘durability.’ There is a significant difference between measuring the durability of concrete structures and measuring the structures’ strength. Compressive strength is a clearly defined property that can be measured directly at a particular point in time using standardized test methods. On the other hand, the properties making concrete durable are many in number. Therefore, durability is more complex to define, measure, and specify.

Concrete durability is defined by the material’s ability to resist weathering action, chemical attack, and abrasion while also maintaining its desired engineering properties such as its compressive strength, permeability, soundlessness, and overall serviceability. To outline what makes concrete durable, many factors must be taken into consideration, including how long the structure is designed to last and whether the building will be subjected to hydrostatic pressure, abrasion, erosion, freeze-thaw cycles, or chemical exposure.

It is important to understand achieving durability is not a one-size-fits-all mechanism. A mix suitable for making a structure durable in the Midwest may be unsuitable for another project exposed to a different environment. For instance, air entrainment is a necessity when a structure is being built in freeze-thaw climates. However, it is not a requirement in dry, desert-like conditions.

Despite the complexity of the many factors affecting concrete durability, the main culprit of deterioration is moisture penetration. As a porous material, concrete allows water (and waterborne contaminants such as chloride ions and sulfates) to migrate through it. Therefore, to make a structure durable, permeation of water through concrete must be prevented. Lowering permeability is the first line of defense against sulfate attack, chloride ingress, corrosion of steel reinforcement, carbonation, alkali-aggregate reaction, and other deterioration mechanisms

When produced using good construction practices, concrete mixes have low permeability. Some good construction practices include using the right mix design, following the relevant building codes, and ensuring adequate measures are taken to place and cure the concrete properly. Well-designed, placed, and cured concrete that follows the American Concrete Institute’s (ACI’s) guidelines remains relatively impermeable and durable as long as it does not crack.

However, cracks and micro-cracks can occur due to various factors, such as early-stage plastic shrinkage, drying shrinkage, thermal changes, excessive stress due to loading, or other elements that can affect the service life of the structure. When water is introduced into the environment, the cracks create a direct pathway for moisture and harmful chemicals to enter the concrete and reach the reinforcing steel. Estimates of durability generally do not take the cracking into account. The underlying danger is the effects of cracks have not been accounted for, which compromises the long-term durability and structural performance of concrete.

Figure 1 This image shows initial leaks in concrete during the construction of a new facility at the Newburyport Wastewater Treatment Facility (NWTF) in Massachusetts.Images courtesy Kryton International.

Some type of waterproofing protection is essential to secure the durability and resulting sustainability of concrete structures. Protective systems can be classified based on their application method: surface-applied systems consist of coatings and sheet membranes (described in ACI Report 515.2R-13, Guide to Selecting Protective Treatments for Concrete), while integral systems consist of an admixture that is added to concrete and protects it from within (described in ACI Report 212.3R-16, Report on Chemical Admixtures for Concrete). Some problems exist with sheet membranes. The installation of membranes calls for careful finishing, temperature control, clean and dry concrete, and dependable surface adhesion. Even the simplest membrane system requires a level of skilled application and the most dedicated tradesperson can make mistakes while applying it, often while battling poor weather conditions. Membrane sheets have to be individually applied, and even the smallest gap between them makes concrete highly susceptible to the influx of water. Moreover, membranes have been known to peel, tear, rip, debond, or puncture, especially during backfilling. Membranes are also usually inaccessible for repairs after installation, increasing the cost of maintenance.

Integral crystalline waterproofing (ICW) technology addresses this issue in a more permanent way. Crystalline waterproofing admixtures are usually a dry-powder mix of Portland cement, fine silica sand, and a proprietary blend of other chemicals. The admixture (typically up to two percent of cementitious content by weight) is used during the mixing stage of concrete.

The principles of ICW technology are similar to the process that occurs during concrete hydration. When cement particles are mixed with water, a chemical reaction occurs. As a result of this chemical reaction, two main types of crystals (calcium silicate hydrate [CSH] and calcium hydroxide [CH]) are generated.

Conventional concrete

The hydration reaction that takes place when cement is mixed with water is responsible for concrete’s setting, hardening, and strength development.However, when crystalline technology is used, the passive admixture in the matrix gets activated as soon as it comes in contact with moisture. On activation, this particular admixture starts crystallization and develops a microstructure of needle-like crystals in concrete.

Concrete modified using crystalline technology

The needle-shaped crystals grow to fill and block the microscopic capillary pores and micro-cracks. As long as moisture is present, crystals continue to grow throughout the concrete, filling up voids, cracks, and capillary pores. Once the concrete has dried, the crystalline chemicals sit dormant until another dose of water (such as a through a new crack) causes the chemical reaction (i.e. crystallization) to restart.

The ability to reactivate in the presence of water gives concrete treated with this admixture the ability to self-seal. When cracks form due to drying shrinkage, setting, seismic activity, or similar, water entering through them causes new crystals to form and grow, blocking the cracks. In the case of this specific admixture, crystals can seal cracks up to 0.5 mm (0.02 in.) in width. Enabling the self-sealing ability of concrete is one of crystalline technology’s most useful features because it helps maintain durability in service and reduce the long-term maintenance costs of a concrete structure. Unlike sheet membranes that could separate from the structure over time—thereby removing all waterproofing—the crystalline admixture stays integral to the slab, protecting concrete from water penetration.

A case study in self-sealing

The Newburyport Wastewater Treatment Facility (NWTF) in Massachusetts is a sludge treatment facility providing biological treatment of wastewater prior to discharge into the Merrimack River.

It can handle up to 12.9 million L (3.4 million gal) per day of wastewater. Originally constructed in 1984, improvements to the plant were recommended in 2012 to modernize and improve its ability to handle current and future water flows. The construction of a new operations, control, and laboratory building on a lot adjacent to the existing facility was part of the renovation. The architects were looking for a permanent waterproofing solution that would continue to self-seal over time.

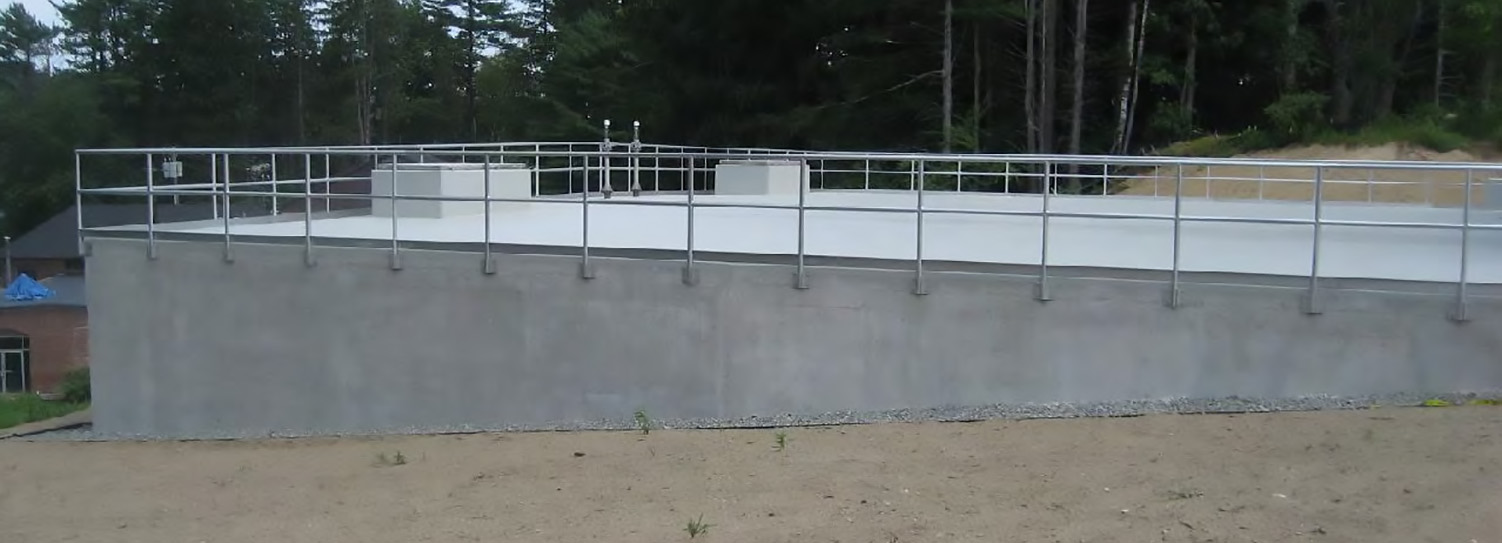

Figure 2 Less than two weeks after the leakage test, the crystals in the admixture self-sealed, leaving zero leaks

A crystalline waterproofing admixture was therefore specified for the project. After the concrete had set, a newly constructed containment tank was filled with water for a leak test to ensure the crystals in the admixture had begun to take effect. After a week, a significant amount of leakage had stopped, but water still seeped through the structure. The contractor onsite was concerned about a potential delay in project completion and was ready to employ a polyurethane injection to stop the leaks. However, waterproofing consultants onsite advised him to wait, assuring him the crystals would form. If the injection was still necessary after two weeks, they promised to recommend an extension of the deadline.

The proprietary crystals in the admixture did begin to take effect, and the walls were completely devoid of moisture. At the end of the two-week period, the injection was not needed. The crystals, having reacted with the water and unhydrated cement, had self-sealed, blocking all the pathways of water through concrete.

Initially skeptical about the concept of self-sealing, the contractor expressed delight with the final result. He was happy with the savings of time and the elimination of additional expenses for injection repairs.

The interlocking needle-like crystals in the waterproofing admixture will continue to grow and protect concrete from water penetration. Six years after the concrete was first poured, the concrete structure remains durable and waterproof.

Conclusion

The crystalline admixture used in the Newburyport case study will provide waterproofing for the life of the concrete structure and enhance the structure’s durability. When specifying the integral admixtures, it is vital the application instructions are followed correctly and good construction practices are put in place onsite.

Crystalline admixtures can be used with existing mix designs, but advice should be sought from the admixture supplier, especially if the concrete provider has limited experience with such materials. The supplier can also provide recommendations for joint detailing, penetrations, and remedial repairs if cracks form that are too large to self-seal.

Crystalline admixtures are useful while waterproofing foundations, even in regions with a high water table. In fact, any concrete subjected to water pressure can use crystalline admixtures for permanent waterproofing. Waterproofing admixtures can be employed in underground parking structures, tunnels, bridges, marine structures, water containment applications, canals, and elevator pits. Further, they can be used with precast, cast-in-place, and shotcrete applications as they are integral to the concrete. By combining the waterproofing step with the placing of concrete, integral admixtures avoid labor-intensive, costly, time-consuming surface preparation and installation costs. They also have the added benefit of eliminating silica-dust exposure in the workplace.

Crystalline admixtures help transform concrete into a waterproofing barrier and enhance the durability and longevity of structures, thereby contributing toward building a better, more sustainable future.

Alireza Biparva, M.A.Sc., LEED GA, works as research and development (R&D) manager and concrete specialist at Kryton International. He has more than 10 years of experience in the field of concrete permeability. Biparva oversees a variety of research projects on Krystol Technology, focusing primarily on concrete permeability studies and the development of innovative products and testing methods for the concrete, waterproofing, and construction industries. He is an active member of the American Concrete Institute (ACI). Biparva

He can be reached at alireza@kryton.com.

SOURCE

Excerpted From Construction Specifier