by ROBIN BRUNET

Canada’s steadily aging infrastructure, combined with the increasing economic need of Infrastructure owners to keep their budgets under control, has resulted in the makers of sealants used In horizontal and vertical applications, concrete restorers, and a vast array of other professionals in the broad restoration field more highly sought for their products than ever.

Mapel Inc. is a prime example. The products from, its Concrete Restoration Systems (CRS) branch help repair damaged concrete in commercial and industrial projects as well as infrastructure settings such as bridges and wastewater systems; these repairs range from the application of waterproofing and corrosion inhibitors to restoration of damaged areas in horizontal, vertical, and overhead structural concrete.

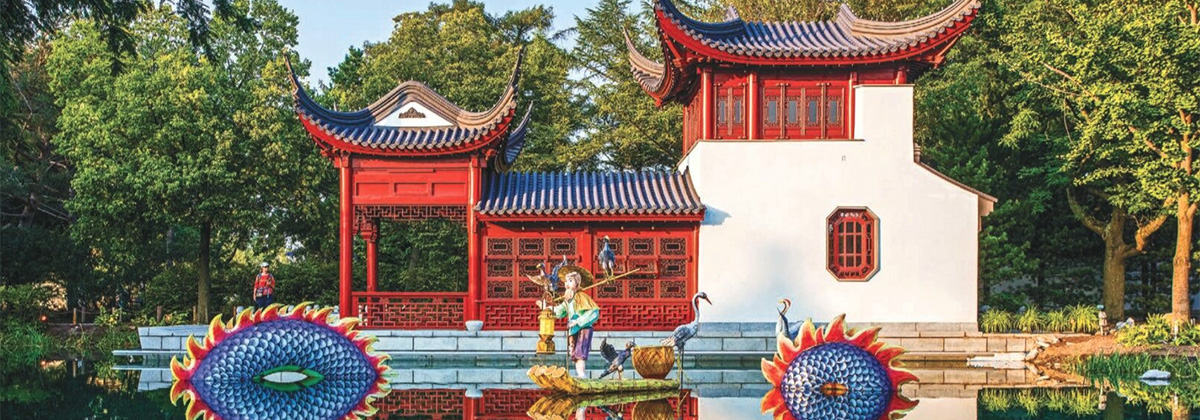

Specifically, the roof tiles of its Chinese-style buildings needed to be repainted because many of them had been damaged when they were imported from overseas. Mapei Technical Services proposed using Elastocolor Coat because it forms a waterproof coating that provides excellent resistance to environ-mental conditions.

Many Mapei products were employed to help restore the roofs: they were rebuilt by applying a one-Inch coat of Planitop 12 SR fibre-reinforced mortar directly on the base metal sheeting. The terracotta tiles were then installed using Mapecem 202 rapid-setting cementitious mortar – an Ideal solution due to the thickness required to secure the curved tiles in place. The jutting gutters around the roofs were installed in some of the areas with Mapecem 202, while in other areas the Granirapid System was used. Elastocolor Coat as the roof finish was approved by the garden owners as well as the original Chinese artisan builders.

Pergantis says, “Elastocolor Paint was used for the walls surrounding the buildings too.” She is referring to an acrylic-based paint that is waterproof and impermeable to aggressive agents present in the surrounding air (the gardens’ walls needed to be restored to their original white colour as well as pro-tected from Montreal’s harsh winter climate).

Mapei is constantly refining existing products and creating new solutions for clients around the world, and Pergantis points to the Mapefloor line of products as invaluable for the restoration of heavy traffic floors such as those found In the food and beverage Industry. Mapefloor CPU is a three-component, self-levelling polyurethane cement mortar with high resistance to chemicals, impacts, and to thermal shocks. applied in thicknesses of six to nine millimetres.

As for another type of surface that in Canada is in constant need of repair- parkades and other vehic-ular thoroughfares – Mapers Mapefloor Finish 415 NA is a two-component, solvent-free, aromatic poly-urethane topcoat specifically designed to provide a protective wear coat for vehicular traffic. Used In combination with the proper Mapefloor parking deck system, the finish protects concrete substrates from water and salt intrusion, while providing a seamless, attractive, slip-resistant wearing surface. ”

In December of 2018, the people at Kryton International were highly anticipating the January 2019 World of Concrete expo in Las Vegas, because, as Kris Till, product manager, explains, “That’s where we introduce installation improvements on our original integral concrete waterproofing product, Krystol Tl. Kryton is highly sought-after for Its unique integral concrete waterproofing technology, Krystol, which chemically reacts with water and unhydrated cement particles to form unique needle-shaped crystals that fill capillary pores and micro-cracks in the concrete’ This permanently blocks the pathways for water and waterborne contaminants, waterproofing the concrete, and replacing the need for traditional waterproofing membranes. The solution is perma-nent as it won’t deteriorate, cannot be damaged, and any moisture introduced to the concrete over its lifespan will Initiate crystallization. This means any micro-cracks that develop will self-seal and prevent water from passing through.

Till says, “Krystol T1 is already the contractors’ choice for reliably waterproofing and repairing concrete as it can be applied from the positive or negative side of the water pressure. But, our single coat installation improvements will now allow contractors to reliably waterproof and repair con-crete structures more efficiently with an improved esthetic finish. With these improvements, we will also now offer a new white version of Krystol T1, which will remove the need to paint light colours [frequently needed in below grade basements] or make that painting process easier to ‘hide.

“Its versatility and proven resistance to hydro-static pressure make it the ideal waterproofing and membrane repair product for below-grade parking structures, basements, walls, elevator and equipment pits, water containment, and water treatment facilities for concrete that is even decades old.”

Till goes on to cite the Krystol Leak Repair System, one of Kryton’s many waterproofing solutions, which actually plays a crucial role in stopping active leaks before the Krystol T1 is applied.-We have specialized in keeping water in or outorconcrete structures for over 45 years and have proven products that fix it the first time”

The Krystol Leak Repair System M an easy three-step process that fixes leaks from the negative side of water pressure, simplifying the repair.”Lots of people don’t realize that you don’t have to excavate or drain your water containment tank to fix that leak with our product,” says Till.

The Krystol Leak Repair System also had installa-tion improvements made in the last two years, which double the speed of installation.

SOURCE

Excerpted From Award Magazine